Model Set up

Create a base model

Step 1 - Create a new file located in London Gatwick and add a building to the site with a simple rectangular block having dimensions 30m x 20m.

Sub-divide the block into 2 zones, an East and a West zone as shown below. The East zone should have East-West length of 10m and the West zone a length of 20m.

Use default model data settings.

Detailed HVAC layout

Step 2 - Set the HVAC model option to “Detailed”.

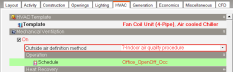

Step 3 - Navigate to HVAC System level and load the “DOAS with DCV and FCU” Detailed HVAC template.

AHU

Step - 4 Navigate to the AHU and open the Edit dialog. On the Outdoor Air System tab of the Air Handling Unit dialog:

-

Under the Recirculation header, set Minimum outdoor air flow rate to 0.

-

Under the Demand Controlled Ventilation header, ensure that the Demand controlled ventilation checkbox is checked.

-

Choose the 3-Indoor Air Quality Procedure (IAQP) for the System outdoor air method item.

-

Press OK.

HVAC zones

Step 5 - Navigate to one of the HVAC zones in the HVAC zone group and open the HVAC zone dialog.

-

On the General tab, under the CO2 and Contaminant Control header, check the CO2 and contaminant control checkbox.

-

On the Target tab, apply the changes to all zones by:

-

Selecting the 3-Multiple (modified settings only) option.

-

Selecting both zones.

-

Press OK

Zone terminal units

Step 6 - Update the terminal units:

a. Navigate to one of the CAV No Reheat terminal units and open the Edit dialog.

b. Check the Control on outdoor air flow checkbox.

Note: you can ignore the Per person ventilation mode child setting of the Control on outdoor air flow checkbox as it is only used when outdoor air ventilation rates are calculated based on a per person rate, and not when using the IAQP.

c. On the Target tab, apply the changes to all zones by:

-

Selecting the 3-Multiple (modified settings only) option.

-

Selecting both zones.

-

Press OK

Note: the CAV No Reheat terminal unit used in this example provides pure CO2 control. Replacing this default CAV terminal with a VAV No Reheat terminal adds free cooling functionality. In this case you would have to change the AHU type to VAV to connect the VAV terminal.

Model Data Settings

Step 7 - Go to Site level and enable the Simulate CO2 concentration site level option.

Step 8 - At building level, on the HVAC tab, ensure that the Mechanical ventilation, On checkbox is checked.

In this case, the zone Outside air definition method setting is used for sizing using fresh air per person, area and ac/h.

Step 9 – At building level, confirm the CO2 setpoint settings on the Activity tab:

Step 10 – Run a simulation over the typical winter period with sub-hourly outputs requested.

Results

When the simulation has finished, check the following sub-hourly results in the Results Viewer:

These will allow you to check the indoor CO2 levels, the fresh air delivery rate in ac/h and the associated fan energy consumption.

You should see results similar to those below, with zone CO2 levels controlled to 900 ppm and the fan operating constantly to achieve this.